VIPAR LED Interview with Edward Rickards

My Brand New VIPAR A200

I recently talked with Edward Rickards (owner of VIPAR) about their grow lights. The lights work great (I’m growing with VIPAR A200 right now) and VIPAR provides great customer service. The VIPAR headquarters are actually located in England making this the first company I’ve interviewed that is stationed outside of the United States. Below is a transcript of our conversation (along with a few pictures I’ve taken):

Nate: Hey Edward, thanks for taking the time to talk with us over here in this corner of the Internet.

First off, I love how you’ve packaged your light. I’ve received lots of LED grow lights now and the packaging is sometimes a mess. Your packaging is simple and useful.

I also really like the design of the light. It feels very durable/high quality and the black paint job looks great.

I’m staring at your diodes here and it appears that you have some sort of plastic/glass lens covering each diode. Is this to concentrate the light more so that the PAR output is higher from a farther distance? In other words is this so that there will be more light at the lower levels of the plant?

Edward: Yes, that is correct. Our LEDs are fitted with 60 degree primary optics. These optics channel the light emitted from the LED down a focused 60 degree angle. This ensures that the emitted light is directed to where it is most needed (on the plants) and enables higher levels of light to reach the lower parts of the plants (as opposed to 90 or 120 degree optics) . Our optics are made of a high-transparency PMMA.

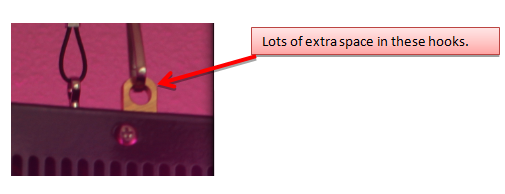

Nate: I really (and I mean really) like the super fatty hooks you put on the back of the VIPAR! The holes are so fat you could fit a finger through them. That will save people from a lot of headaches. The extras (the climbing hooks) that you sent with the light are also a nice addition.

Edward: Thanks Nate. Functionality – It’s what VIPAR is all about.

Nate: What kind of warranty can customers expect if they buy a VIPAR grow light?

Edward: We stand behind our products to the fullest extent. All VIPAR grow lights come with a solid 3 year warranty. If a customer contacts us to say that their VIPAR light has developed a fault, we will repair/replace the light in the earliest instance. All repairs are handled by VIPAR and take place in the UK or Canada depending on the customer’s location.

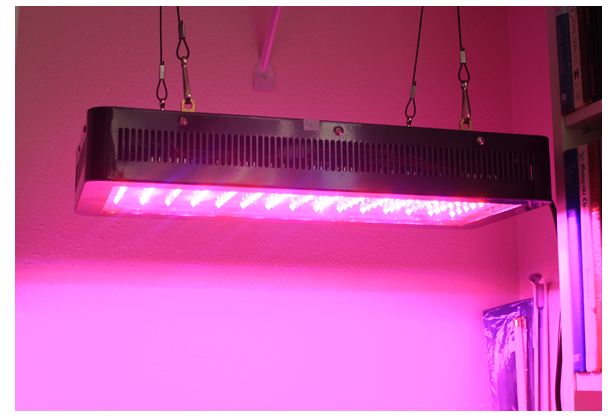

Here’s my A200 in action.

Nate: Is there a trial period? If so, for how long?

Edward: Each and every VIPAR grow light is guaranteed by our 90 day returns policy. We have total confidence in our products and our returns policy is testament to this. If for any reason a customer is not entirely happy with their light, they would simply need to contact us to arrange a swift return.

Nate: Some of my readers are concerned about the noise level of LED lights. Would you consider this a quiet light?

Edward: Yes, I think so. The benefit of using two 120mm fans (A200 & A300) as opposed to multiple (four plus) smaller fans is significant not only on the more obvious heat dissipation front but in reduced noise levels also. Due to its size, the A100 is unable to incorporate a large fan into its design, so it uses three 80mm fans. Noise is kept to a minimum once again without heat management being compromised.

My plants are doing great under the VIPAR

Nate: What steps have you at VIPAR made to ensure your light has a proper heat management system in place (so the diodes don’t overheat and break)? Any information you can share with us about the heat sink design and materials used?

Edward: All VIPAR grow lights utilise an extremely effective heat management system designed to heavily reduce operating temperatures which in turn increases the life span of our grow lights and their ability to sustain optimal performance.

The core components to our heat management system are:

– MCPCB

The MCPCB is essential for high powered LED applications due to the amount of heat that the LEDs are capable of generating.

– Aluminum plate

The aluminum plate sits directly underneath the MCPCB. The heat generated by the LEDs passes through the MCPCB and the aluminum plate then disperses the heat over a wider area.

– Finned aluminum heat sinks

For each VIPAR light, there are three aluminum heat sinks, one for each section of the MCPCB. The heat sinks effectively “pull” the heat from the aluminum plate and sets it down its fins.

– High-efficiency fans

High-efficiency fans then dissipate the extracted heat through the side vents on the lights.

Our heat management system is of a superior quality and guarantees optimal performance grow after grow.

Nate: What spectral wave lengths are used in your light? Anything out of the ordinary here?

No space? No problem.

Edward: The VIPAR spectrum consists of the following light wavelengths: 620-670nm, 420-470nm and 720-740nm. Our research has shown us that blue, red and far red light in the correct balance is all that is required to enable strong and healthy plant growth in our favourite plants.

The VIPAR spectrum has high concentrations of red (620nm-670nm) light which drives the targeted plants primary photosynthetic responses. Red light is essential to proper flowering production.

The low concentration of far red light (720nm-740nm) that our lights produce ensures healthy plant morphogenesis and stimulates flower induction. Getting the right ratio of red and far red light is essential to optimising the photosynthetic and photomorphogenic responses.

The blue light (420nm-470nm) in the VIPAR spectrum stimulates the plants phototrophic processes and is essential for healthy growth throughout both the vegetative and flowering stages of the plant’s life cycle.

The VIPAR spectrum ensures that the light requirements of all sun-loving, flowering plants are met throughout their entire life cycle.

Nate: What market are you targeting with your light (dispensaries, greenhouses, small growers)?

Edward: Our lights cater to the needs of all indoor growers. We can match a suitable light to most grow setups. So from micro grows to larger scale grows, VIPAR provides.

Nate: What makes your lights unique or different from the other LED grow lights on the market?

Edward: We provide the indoor growing market with a series of high-performance, reliable and cost-effective grow lights that have been fine tuned over time to deliver both impressive results and unmatched reliability . Our uniqueness comes down to the emphasis that we place on what we consider to be the two most important elements in LED grow lighting – performance and reliability.

In terms of performance, you would be hard pushed to find a grow light of equivalent cost and wattage that will deliver the results that a VIPAR light can achieve. The combination of the VIPAR spectrum, our high-powered 3W LEDs and our 60 degree primary optics provides sun-loving, flowering plants with the power and light qualities needed to achieve optimal growth.

VIPAR grow lights are designed to meet the demands of frequent growing. From our powerful heat management systems to the LED drivers that we have customised to include high-quality electrolytic capacitors from Japan, no stone was left unturned in regards to enhancing the reliability of our grow lights. Our grow lights ensure that your grows will be powered and protected for years to come.

VIPAR grow lights are designed to meet the demands of frequent growing. From our powerful heat management systems to the LED drivers that we have customised to include high-quality electrolytic capacitors from Japan, no stone was left unturned in regards to enhancing the reliability of our grow lights. Our grow lights ensure that your grows will be powered and protected for years to come.

It’s not just our grow lights that make us stand out from the crowd but the way we conduct ourselves in business also. We pride ourselves in providing exceptional levels of customer support and our after-service is second to none. We want people to feel confident in choosing a VIPAR grow light, knowing that they will never be misinformed and that they are getting a quality product with service to match. This is the VIPAR way.

Nate: One of my readers mentioned to me that your light looks like the diamond series lights from AdvancedLED. Are you using the same manufacturer?

Edward: I can see the resemblance between our grow lights and the “Diamond Series” grow lights. We share a similar casing, but that is where the similarity ends. They use an often talked about Chinese factory, we are partnered with an entirely different one.

Nate: How big of an operation are you running? Most of the companies I talk to only have one or two employees and then they outsource the assembly/manufacturing to China.

Edward: VIPAR is a small but focused company dedicated to delivering the very best in artificial plant lighting to indoor growers across the globe. Our main base of operation is located in the United Kingdom. This is where all our research, design and development takes place. We are in the process of establishing a second base of operation in Canada, that will manage North American after-service and distribution. All VIPAR grow lights are proudly assembled in China. In early 2011, we partnered up with a wonderful electronics factory in China that share our core values of performance and reliability. Through our combined efforts we are able to provide what we believe to be the most affordable, reliable and effective LED grow lights on the planet.

Thanks for giving me the opportunity to discuss VIPAR.

Nate: Thanks for taking the time to talk about your lights. I’ve enjoyed your honesty and willingness to share information. I’m currently using the VIPAR A200 in one of my grows and I’ll be posting a technical review of the light soon.

Hey nate excellent interview……….wondering why coverage area wasn’t dicussed, due to the 60degree lenses, I still believe that 90degree is great blend between coverage and penetration, at 60 you got too keep the lights way higher to against bleaching thus voiding any penetration advantages. Not to mention the par/umol (inverse square law) will drop significantly due to the height requirements(imo)…Also no mention of the actual led manufctrs (epistar/semiled/optoled <<my guesses/ readily available/good price point in china) in their panel, would have been good info….

Oh btw do the fans in your vipar push or draw out the air:)

Hey Psulvr,

I’ll be coming out with a more technical review of the light in the near future. The beam angle argument is a difficult one. For the past year or so I’ve personally preferred 60 degree lenses and most of the high end LED grow lights have been going with 60 degrees as well (there are a few exceptions of course).

Anyways, thanks for the great questions and comments. I’ll be answering your other questions in the technical review.

Best,

Nate J.

Oh by the way, the Vipar lights have push fans.

The diodes used are a combination of EpiLED and Bridgelux diodes.

Great to see a review of a UK-based company – no import and duty to pay!! I hear good things of these panels from diaries and feedback I’ve read and they’ve been very quick to answer queries when I’ve tried contacting them. It would be nice to see a broader range of spectrums available, than just the red, far red and blue they currently offer – IR and UV, for instance. It would also be good to see 1w diodes available. Their A100 (the 100w panel and the smallest they make) would likely fry most plants in a microgrow.